Users:Structural Optimization/Design Variables/Nodal Thickness

(→Example of a Complete Input Block) |

(→Model description) |

||

| (12 intermediate revisions by one user not shown) | |||

| Line 5: | Line 5: | ||

=== Short Info === | === Short Info === | ||

| − | With this design variable, the nodal thickness can be optimized. This is especially usefull in combination with | + | With this design variable, the nodal thickness can be optimized. This is especially usefull in combination with SHELL8 elements since these elements can have a non-constant thickness based on the nodal thicknesses. |

| − | The thickness at each node can be initialized | + | The thickness at each node can be initialized in the input file. Alternatively, the initial thickness is computed as the mean thickness of the surrounding elements. |

=== Parameters in the Input File === | === Parameters in the Input File === | ||

| Line 18: | Line 18: | ||

!Description | !Description | ||

|- | |- | ||

| − | ! | + | !TYPE |

| − | | | + | |NODE ''ID'', ND-SET ''ID'' |

| − | |Linking to | + | |Linking to previously defined nodes or node sets |

|- | |- | ||

| − | ! | + | !SUBTYPE |

| − | | | + | |THICKNESS |

| − | | | + | |To obtain the desired design variable |

| − | + | ||

|- | |- | ||

|colspan="3" style="background:#efefef;"| Optional Parameters | |colspan="3" style="background:#efefef;"| Optional Parameters | ||

| Line 33: | Line 32: | ||

!Description | !Description | ||

|- | |- | ||

| − | ! | + | !BOUND |

| − | |'' | + | |OPT-BOUND ''ID'' |

| − | | | + | |Linking to a bound defined in BOUND block. |

| − | + | Remark: only SCALAR_BOUND is valid. | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

|- | |- | ||

|} | |} | ||

| Line 48: | Line 42: | ||

=== Example of a Complete Input Block === | === Example of a Complete Input Block === | ||

| − | This design variable can be defined for one node of for a nodal set. | + | This design variable can be defined for one node of for a nodal set. It is good practice to add a bound to the thickness design variables to avoid unrealistic values. In general, it is obvious to choose an upper and lower limit. Since the thickness is a scalar design variable, only SCALAR_BOUND is appropriate. |

<pre> | <pre> | ||

| Line 60: | Line 54: | ||

=== Model description === | === Model description === | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | This example considers the thickness optimization of the Kresge auditorium. In a first step, the shape of the auditorium was optimized for minimal strain energy under dead load (cfr. PhD M. Firl) with constant thickness. The resulting shape is presented in the figure. In a second step, the thickness of the optimized shape is optimized. Strain energy under dead load is again used as the objective function. The design variables are the thicknesses at every node, constrained between 0.10 and 0.03 m. The shape of the shell is fixed. | ||

| − | + | [[File:shape.jpg |400px]] | |

| − | + | === Results === | |

| + | In the figures, the thickness distribution and the Von Mises stresses in the top plane are shown for 50 optimization steps starting from a constant thickness of 0.05 m. It is clear that the largest part of the shell works very efficient on membrane forces and thus the thickness can be the minimal thickness. Only the support regions are subjected to bending, so the stresses can be reduced significantly by increasing the thickness to the maximal thickness. | ||

| + | [[File:MIT_objSE_thickness.gif| Thickness]] | ||

| + | [[File:MIT_objSE_vmtop.gif | Von Mises top]] | ||

| − | === | + | === Input File === |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | to be added | |

Latest revision as of 09:49, 22 October 2010

Contents |

General Description

Short Info

With this design variable, the nodal thickness can be optimized. This is especially usefull in combination with SHELL8 elements since these elements can have a non-constant thickness based on the nodal thicknesses.

The thickness at each node can be initialized in the input file. Alternatively, the initial thickness is computed as the mean thickness of the surrounding elements.

Parameters in the Input File

| Compulsory Parameters | ||

| Parameter | Values, Default(*) | Description |

|---|---|---|

| TYPE | NODE ID, ND-SET ID | Linking to previously defined nodes or node sets |

| SUBTYPE | THICKNESS | To obtain the desired design variable |

| Optional Parameters | ||

| Parameter | Values, Default(*) | Description |

| BOUND | OPT-BOUND ID | Linking to a bound defined in BOUND block.

Remark: only SCALAR_BOUND is valid. |

Example of a Complete Input Block

This design variable can be defined for one node of for a nodal set. It is good practice to add a bound to the thickness design variables to avoid unrealistic values. In general, it is obvious to choose an upper and lower limit. Since the thickness is a scalar design variable, only SCALAR_BOUND is appropriate.

OPT-VAR 1 TYPE=NODE 100 SUBTYPE=THICKNESS BOUND=OPT-BOUND 1 TYPE=ND-SET 2 SUBTYPE=THICKNESS BOUND=OPT-BOUND 1

A complete test example

Model description

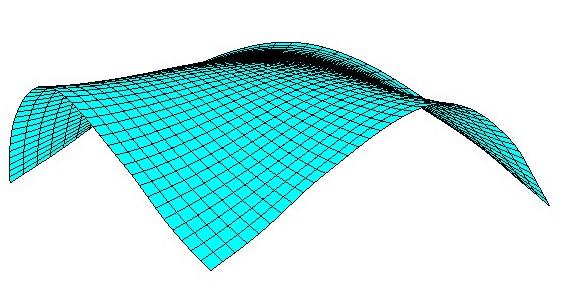

This example considers the thickness optimization of the Kresge auditorium. In a first step, the shape of the auditorium was optimized for minimal strain energy under dead load (cfr. PhD M. Firl) with constant thickness. The resulting shape is presented in the figure. In a second step, the thickness of the optimized shape is optimized. Strain energy under dead load is again used as the objective function. The design variables are the thicknesses at every node, constrained between 0.10 and 0.03 m. The shape of the shell is fixed.

Results

In the figures, the thickness distribution and the Von Mises stresses in the top plane are shown for 50 optimization steps starting from a constant thickness of 0.05 m. It is clear that the largest part of the shell works very efficient on membrane forces and thus the thickness can be the minimal thickness. Only the support regions are subjected to bending, so the stresses can be reduced significantly by increasing the thickness to the maximal thickness.

Input File

to be added

| Whos here now: Members 0 Guests 0 Bots & Crawlers 1 |