Users:General FEM Analysis/Elements Reference/Membrane1

Contents |

General Description

Element Type

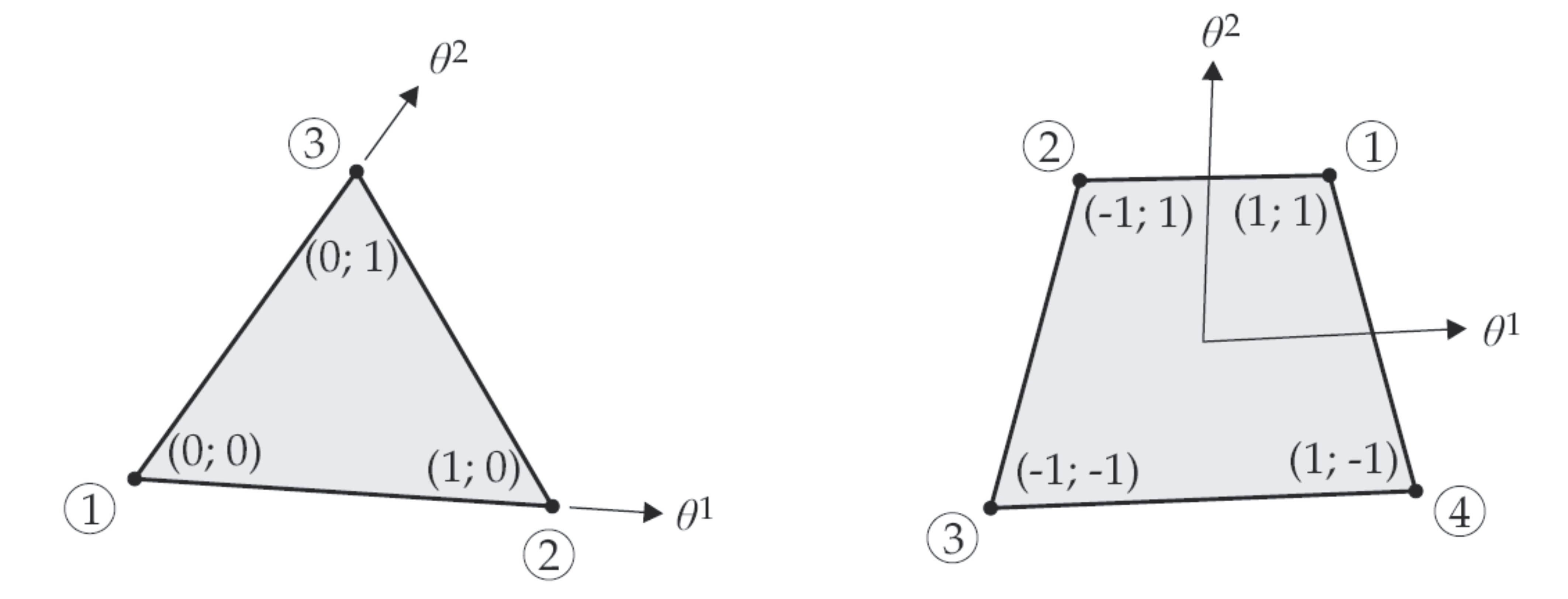

- This membrane element is a plane stress element with 3 degrees of freedom per node

- The membrane element neglects the bending stiffness

- The ratio of the thickness and the lengths in the other two directions is much smaller than one ( t/Lx << 1 and t/Ly << 1), the membrane is reduced to its mid-surface

- The thickness is constant over the element

Degrees of Freedom

The membrane element uses the 3 translatoric degrees of freedom, DISP_X, DISP_Y, DISP_Z.

Input Parameters

Parameter Description

| Compulsory Parameters | ||

| Parameter | Values, Default(*) | Description |

|---|---|---|

| MAT | EL-MAT int | Number for the used Material

e.g. MAT=EL-MAT 1 |

| THICKNESS | Thickness of the membrane | |

| A_X, A_Y, A_Z

B_X, B_Y, B_Z |

Definition of the principal directions of the surface to define the prestress directions. (see description below) | |

| SIG11

SIG22 SIG12 |

Prestress state of the membrane. (see description below) | |

| Optional Parameters | ||

| Parameter | Values, Default(*) | Description |

| LAGRANGE | TOTAL, UPDATED | Definition of lagrange type. UPDATED for form finding and TOTAL for statics or dynamics. (e.g. LAGRANGE=UPDATED) |

Example of a Complete Input Block

EL-PROP 1 : MEMBRANE1 MAT= EL-MAT 1 THICKNESS=1.0 PRESTRESS SIG11=1.0 SIG22=1.0 SIG12=0.0 A_X=1.0 A_Y=0.0 A_Z=0.0 B_X=0.0 B_Y=1.0 B_Z=0.0

Element Loading

Pressure

Pressure load -- characterized by its application in the current configuration, including direction and application area -- is implemented for the Membrane1 element. Note that it may also be included in the form-finding in order to define pressurized cushions, etc.

Dead Load

Dead load is implemented. It takes the thickness of the element and the density of the material which is then multiplied by the assigned acceleration value in the proposed direction.

Snow Load

Snow load is implemented. It considers the projected surface area of the element w.r.t. the load direction that is applied.

Theory

The theory and finite element formulation is described in detail in [1] , [2] and [3].

For the correct use of the membrane element and the interpretation of related results, the following aspects should be considered:

Material parameter

With the parameter MAT the material, that would be used in the calculation, for the membrane element is defined. The following materials are tested for the membrane element:

- linear elastic isotropic

- linear elastic orthotropic (Münsch-Reinhardt)

- multilinear elastic isotropic

- elastoplastic isotropic

- material on the basis of response functions

Thickness parameter

The parameter THICKNESS defines the thickness of the membrane. The thickness is assumed constant over the element.

Prestress directions on the surface

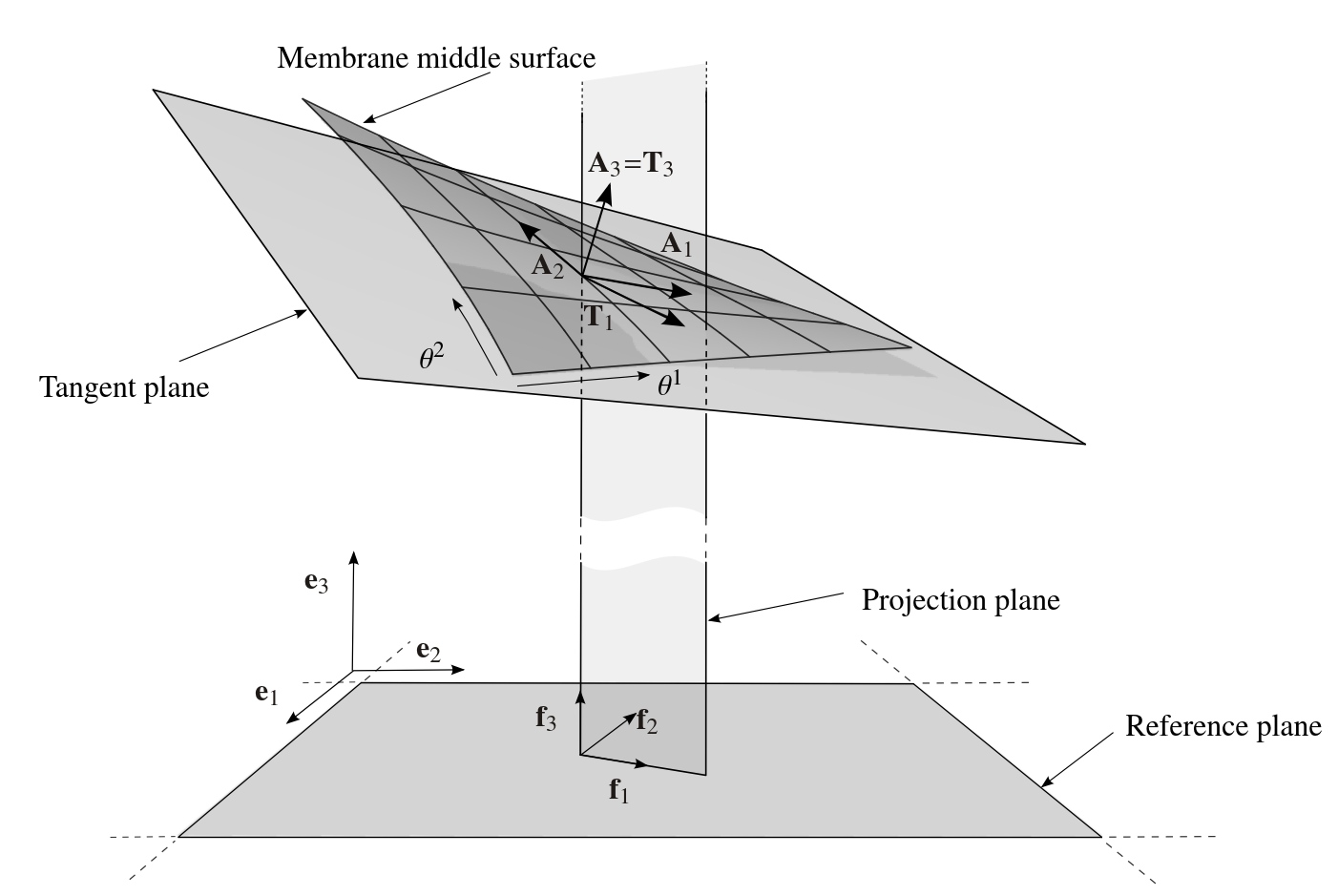

The parameters A_X, A_Y, A_Z and B_X, B_Y, B_Z are used to define the prestress directions on the surface, which is necessary in case of anisotropic prestress conditions. In this approach the principal directions of the prestress are defined in a plane area (see figure below). The definition of the area is given by the two vectors f1 and f2. The normal vector of the area can be calculated with the cross product of the in plane vectors f3=f1 x f2. Afterwards the line of intersection T1 of the area which is given by f1 and f3 and the curved surface can be calculated. In this approach T1 is interpreted as the first principal direction of the prestress on the curved surface. With the assumption that T3 is equal to the surface normal vector A3 (not normalized), the second direction of the prestress is calculated as T2=T1 x T3. W.r.t. the parameters for the input file, only the plane area with the vectors f1 and f2 has to be defined. Referring to the depicted approach the vector A defines the vector f1 and the vector B defines the vector f2.

Prestress state

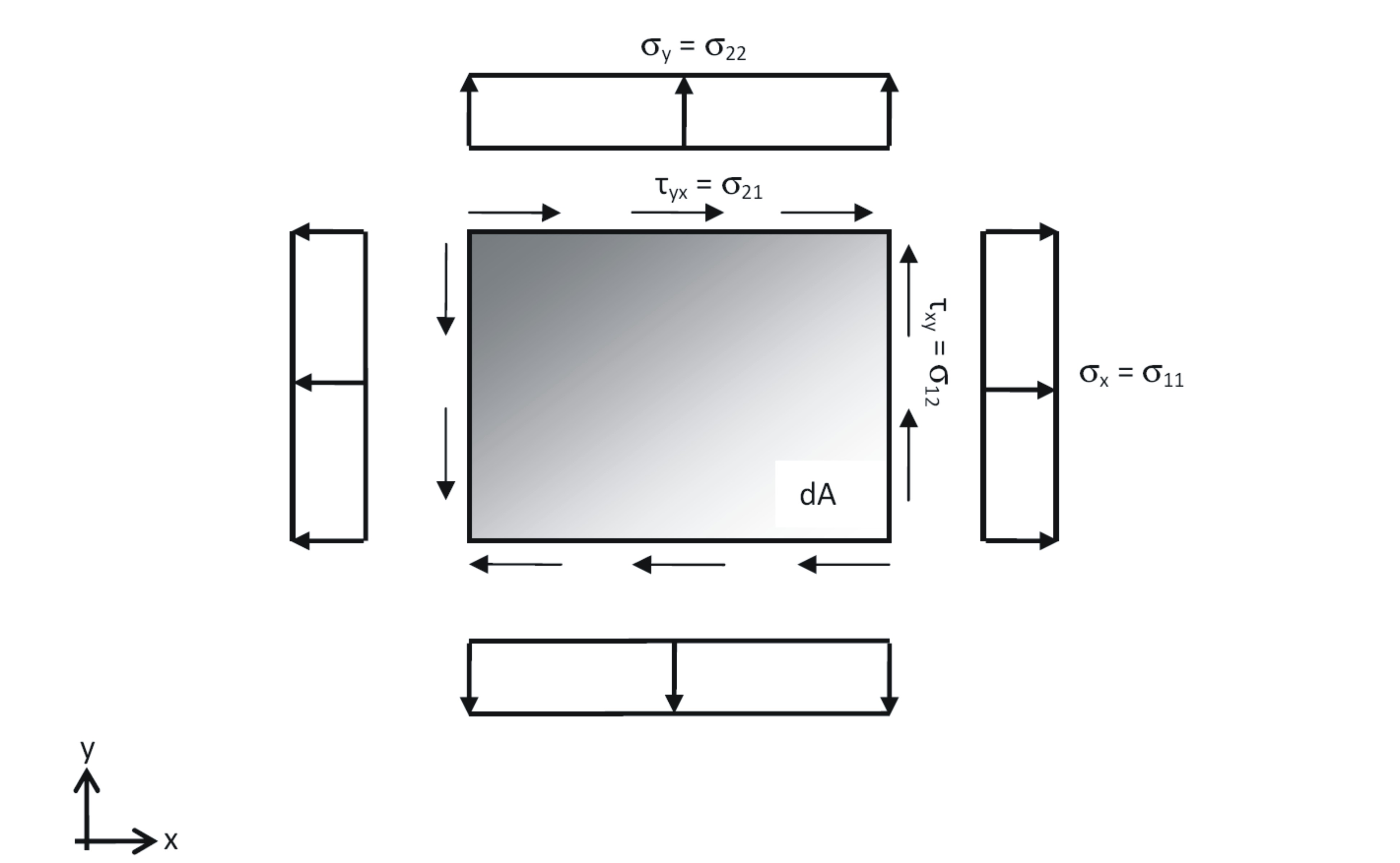

SIG11, SIG22, SIG12 describes the prestress of the membrane element. The element is based on the plane stress assumption. Due to that only normal and shear stresses in the midplane have to be defined. SIG11 is the stress acting in T1, SIG22 acting in T2 and SIG12 is the in-plane shear, whereas SIG12=SIG21 (see figure below).

Lagrange type

With the (optional) LARANGE parameter it is possible to switch between form finding and statical/dynamic analysis. For the value UPDATED the element is for form finding and for the value TOTAL the element is for statical/dynamical analysis. It is important that the LANGRANGE parameter match to the type of analysis.

Tests and Benchmarks

The element Membrane1 has successfully been applied in 3D in various linear and geometrically non-linear static applications, as well as in dynamic analyses and form-finding.

Benchmark examples

- form-finding of a four-point sail: ..\examples\benchmark_examples\analyses\formfinding_membrane1_I\cbm_4_point_Fofi.txt

- static geometrically non-linear analysis of a prestressed membrane under snow load: ..\examples\benchmark_examples\analyses\stanln_membrane1_I\cbm_4_point.txt

References

- ↑ Dieringer, F.: Implementierung eines geometrisch nichtlinearen Membranelements in einer objektorientierten Programmierumgebung, Master's Thesis, Lehrstuhl für Statik, Technische Universität München, 2009

- ↑ Linhard, J.: Numerisch-mechanische Betrachtung des Entwurfsprozesses von Membrantragwerken, Lehrstuhl für Statik, Technische Universität München, 2009

- ↑ Dieringer, F.: Numerical Methods for the Design and Analysis of Tensile Structures, Lehrstuhl für Statik, Technische Universität München, 2014

| Whos here now: Members 0 Guests 0 Bots & Crawlers 1 |