Users:General FEM Analysis/Analyses Reference/Cutting Pattern

(→Parameter Description) |

|||

| (27 intermediate revisions by 2 users not shown) | |||

| Line 3: | Line 3: | ||

== General Description == | == General Description == | ||

| − | Cutting pattern generation determines a plane and (optimally) stress-free geometry which can be reassembled to build a membrane with a certain prestress and shape (as it was determined in Formfinding). | + | Cutting pattern generation determines a plane and (optimally) stress-free geometry which can be reassembled to build a membrane with a certain prestress and shape (as it was determined in Formfinding).<ref name="Dieringer"> Dieringer, F.: Numerical Methods for the Design and Analysis of Tensile Structures, Dissertation Lehrstuhl für Statik, 2014 </ref> |

| + | Prerequisites: [[Users:Form_Finding|Formfinding]] and [[Users:General_FEM_Analysis/Analyses_Reference/Geodesic_Lines|Geodesic Line Search]] | ||

| + | |||

| + | '''Note''' that an instruction is included in the "Membran-Workshop" documents. | ||

=== Structure of Equation System === | === Structure of Equation System === | ||

| Line 10: | Line 13: | ||

A nonlinear problem is formulated by the equation '''r''' = '''f'''_int('''u''') where '''r''' specifies the residual vector and '''f'''_int defines the internal forces respectively. In general, the internal forces depend on the actual displacement field '''u'''. Thus, the equation is nonlinear with respect to the a priori unknown equilibrium displacements. | A nonlinear problem is formulated by the equation '''r''' = '''f'''_int('''u''') where '''r''' specifies the residual vector and '''f'''_int defines the internal forces respectively. In general, the internal forces depend on the actual displacement field '''u'''. Thus, the equation is nonlinear with respect to the a priori unknown equilibrium displacements. | ||

| − | At the equilibrium point the residual vector is equal to zero. The above specified nonlinear problem is linearized for the actual displacement state and solved e.g. by a Newton-Raphson scheme where the residual vector is used to compute incremental displacements by '''K'''_t '''u'''_inc = '''r'''. | + | At the equilibrium point the residual vector is equal to zero. The above specified nonlinear problem is linearized for the actual displacement state and solved e.g. by a Newton-Raphson scheme where the residual vector is used to compute incremental displacements by '''K'''_t '''u'''_inc = '''r'''. |

| − | + | ||

== Input Parameters == | == Input Parameters == | ||

| Line 58: | Line 60: | ||

!BC_CONFIGURATION | !BC_CONFIGURATION | ||

|TYPE ''int'' | |TYPE ''int'' | ||

| − | |The type of boundary condition configuration, | + | |The type of boundary condition configuration, for each part one type must be given. 1... first and last node, 2... last two nodes in the list, 3... first two nodes in the list, 4... largest distance between nodes. |

|- | |- | ||

!RELAXATION_METHOD | !RELAXATION_METHOD | ||

| Line 65: | Line 67: | ||

|- | |- | ||

!FLATTENING_AREA | !FLATTENING_AREA | ||

| − | |0 or 1 | + | |0 or 1 or 2 |

| − | |0... prestress area. 1... mean surface normal. | + | |0... prestress area. 1... mean surface normal. 2... cylinder with RADIUS and RO_X,RO_Y,RO_Z. |

|- | |- | ||

!PATTERNING_METHOD | !PATTERNING_METHOD | ||

| Line 72: | Line 74: | ||

|Definition of the patterning method. GALERKIN... principle of virtual work. LS_NR and LS_CG... optimization problem solved with Newton-Raphson or Conjugate Gradient approach. | |Definition of the patterning method. GALERKIN... principle of virtual work. LS_NR and LS_CG... optimization problem solved with Newton-Raphson or Conjugate Gradient approach. | ||

|- | |- | ||

| − | |colspan="3" style="background:#efefef;"| Optional | + | |colspan="3" style="background:#efefef;"| Optional parameters for the consideration of seam lines |

|- | |- | ||

| − | ! | + | !EQUAL_SEAM_LINES |

| − | |- | + | |TRUE or FALSE |

| − | |Includes the seam | + | |Includes the seam lengths into the cutting pattern analysis and minimizes the length difference of common edges. |

| + | |- | ||

| + | !PENALTY_FAC | ||

| + | |''int'' | ||

| + | |Definition of a penalty factor for the seam line length optimization. | ||

| + | |- | ||

| + | !SEAM_LINES | ||

| + | |TRUE or FALSE | ||

| + | |Includes the increased stiffness along the seam lines into the analysis. | ||

| + | |- | ||

| + | !SEAM_AREA | ||

| + | |''float'' | ||

| + | |Definition of the seam area for an analysis which includes the seam lines. | ||

| + | |- | ||

| + | !SEAM_MATERIAL | ||

| + | |''int'' | ||

| + | |Definition of the seam line material for an analysis which includes the seam lines. | ||

| + | |- | ||

| + | |- | ||

| + | |colspan="3" style="background:#efefef;"| Optional parameters for a cylinder projection before flattening the stripes | ||

| + | |- | ||

| + | !RADIUS | ||

| + | |''float'' | ||

| + | |If a cylinder is defined for the projection area (FLATTENING_AREA=2) Definition of the cylinder radius. | ||

| + | |- | ||

| + | !RO_X; RO_Y; RO_Z | ||

| + | |''float'' | ||

| + | |Definition of the root point for the cylinder as a projection area. | ||

| + | |- | ||

| + | |- | ||

| + | |colspan="3" style="background:#efefef;"| Optional parameters for a possible restart analysis after the cutting-pattern generation | ||

| + | |- | ||

| + | !MOUNTING_ANALYSIS | ||

| + | |''int'' | ||

| + | |Starts the mounting analysis after the cutting pattern generation. | ||

| + | |- | ||

| + | !MOUNTING_ANALYSIS_TYPE | ||

| + | |FULL or RESTART or INCREMENTAL | ||

| + | |Definition of the mounting analysis type. | ||

|} | |} | ||

| Line 82: | Line 122: | ||

<pre> | <pre> | ||

| − | PC-ANALYSIS 1: | + | PC-ANALYSIS 1: CUTTING_PATTERN |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

DOMAIN = EL-DOMAIN 1 | DOMAIN = EL-DOMAIN 1 | ||

| − | + | MAX_ITER_EQUILIBRIUM = 20 | |

| − | MAX_ITER_EQUILIBRIUM = | + | EQUILIBRIUM_ACCURACY = 1e-06 |

| − | EQUILIBRIUM_ACCURACY = 1e- | + | COMPCASE = LD-COM 1 |

| − | + | OUTPUT = PC-OUT 1 | |

| − | + | PATTERN = PART 1,3 | |

| − | + | BC_CONFIGURATION = TYPE 4,4 | |

| − | + | SOLVER = PC-SOLVER 1 | |

| − | + | RELAXATION_METHOD=STATIC !NONE, STATIC, GALERKIN, COMBINED | |

| − | + | FLATTENING_AREA=1 !0 ...Prestress area, 1 ...Mean surface normal | |

| − | + | PATTERNING_METHOD=GALERKIN !LS_NR, GALERKIN, LS_CG, NONE | |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | ! | + | |

| − | + | ||

| − | + | ||

| − | + | ||

</pre> | </pre> | ||

== Example == | == Example == | ||

| − | The following simple example shows | + | The following simple example shows the cutting pattern analysis of two parts from a four-point sail. It uses a static relaxation method, the flattening area is the mean surface normal and a Galerkin approach is used for the patterning method. |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

{| | {| | ||

| − | |[[File: | + | |[[File:Benchmark_cutpat_4point.png]] |

|} | |} | ||

| − | The | + | The cutting pattern of the two stripes is shown in the picture below. |

{| | {| | ||

| − | |[[File: | + | |[[File:Benchmark_cutpat_4point_relaxed.png]] |

| − | + | ||

| − | + | ||

| − | + | ||

| − | + | ||

|} | |} | ||

| + | |||

| + | === Benchmark examples === | ||

| + | * four point sail with coarse discretization: ..\examples\benchmark_examples\analyses\cutPat_Membrane1\cbm_CutPat.dat | ||

| + | * four point sail with coarse discretization and automatic mounting analysis after restart: ..\examples\benchmark_examples\analyses\cutPatWithMounting_Membrane1\cbm_CutPatWithMounting.dat | ||

| + | * four point sail with linear elastic material and membrane 1 elements (not included in regular benchmarks due to amount of time for running, but working!) ..\examples\benchmark_examples\analyses\cutting_patterning_membrane1_I\x_cbm_4_point_patterning.txt | ||

== References == | == References == | ||

<references/> | <references/> | ||

Latest revision as of 08:16, 27 April 2020

Contents |

General Description

Cutting pattern generation determines a plane and (optimally) stress-free geometry which can be reassembled to build a membrane with a certain prestress and shape (as it was determined in Formfinding).[1]

Prerequisites: Formfinding and Geodesic Line Search

Note that an instruction is included in the "Membran-Workshop" documents.

Structure of Equation System

A nonlinear problem is formulated by the equation r = f_int(u) where r specifies the residual vector and f_int defines the internal forces respectively. In general, the internal forces depend on the actual displacement field u. Thus, the equation is nonlinear with respect to the a priori unknown equilibrium displacements.

At the equilibrium point the residual vector is equal to zero. The above specified nonlinear problem is linearized for the actual displacement state and solved e.g. by a Newton-Raphson scheme where the residual vector is used to compute incremental displacements by K_t u_inc = r.

Input Parameters

Parameter Description

| Compulsory Parameters | ||

| Parameter | Values, Default(*) | Description |

|---|---|---|

| PC-ANALYSIS | int : CUTTING_PATTERN | Keyword of analysis with analysis ID |

| SOLVER | PC-SOLVER int | Linking to a linear solver (direct or iterative) |

| OUTPUT | PC-OUT int | Linking to output objects (specifies the type of output format, e.g. GiD) |

| COMPCASE | LD-COM int | Linking to computation case object which specify the boundary conditions (loading and supports). Only a single computation case is allowed. |

| DOMAIN | EL-DOMAIN int | Linking to the domain the analysis should work on |

| MAX_ITER_EQUILIBRIUM | int | Maximum number of equilibrium iterations that are allowed. |

| EQUILIBRIUM_ACCURACY | float | Equilibrium accuracy that has to be reached for convergence. The convergence is checked with the L2 norm of the incremental displacements. |

| PATTERN | PART int | The parts which should be included in the analysis, separation with comma. |

| BC_CONFIGURATION | TYPE int | The type of boundary condition configuration, for each part one type must be given. 1... first and last node, 2... last two nodes in the list, 3... first two nodes in the list, 4... largest distance between nodes. |

| RELAXATION_METHOD | STATIC or NONE or GALERKIN or COMBINED | Definition of relaxation method. |

| FLATTENING_AREA | 0 or 1 or 2 | 0... prestress area. 1... mean surface normal. 2... cylinder with RADIUS and RO_X,RO_Y,RO_Z. |

| PATTERNING_METHOD | GALERKIN or LS_NR or LS_CG or NONE | Definition of the patterning method. GALERKIN... principle of virtual work. LS_NR and LS_CG... optimization problem solved with Newton-Raphson or Conjugate Gradient approach. |

| Optional parameters for the consideration of seam lines | ||

| EQUAL_SEAM_LINES | TRUE or FALSE | Includes the seam lengths into the cutting pattern analysis and minimizes the length difference of common edges. |

| PENALTY_FAC | int | Definition of a penalty factor for the seam line length optimization. |

| SEAM_LINES | TRUE or FALSE | Includes the increased stiffness along the seam lines into the analysis. |

| SEAM_AREA | float | Definition of the seam area for an analysis which includes the seam lines. |

| SEAM_MATERIAL | int | Definition of the seam line material for an analysis which includes the seam lines. |

| Optional parameters for a cylinder projection before flattening the stripes | ||

| RADIUS | float | If a cylinder is defined for the projection area (FLATTENING_AREA=2) Definition of the cylinder radius. |

| RO_X; RO_Y; RO_Z | float | Definition of the root point for the cylinder as a projection area. |

| Optional parameters for a possible restart analysis after the cutting-pattern generation | ||

| MOUNTING_ANALYSIS | int | Starts the mounting analysis after the cutting pattern generation. |

| MOUNTING_ANALYSIS_TYPE | FULL or RESTART or INCREMENTAL | Definition of the mounting analysis type. |

Example of a Complete Input Block

PC-ANALYSIS 1: CUTTING_PATTERN DOMAIN = EL-DOMAIN 1 MAX_ITER_EQUILIBRIUM = 20 EQUILIBRIUM_ACCURACY = 1e-06 COMPCASE = LD-COM 1 OUTPUT = PC-OUT 1 PATTERN = PART 1,3 BC_CONFIGURATION = TYPE 4,4 SOLVER = PC-SOLVER 1 RELAXATION_METHOD=STATIC !NONE, STATIC, GALERKIN, COMBINED FLATTENING_AREA=1 !0 ...Prestress area, 1 ...Mean surface normal PATTERNING_METHOD=GALERKIN !LS_NR, GALERKIN, LS_CG, NONE

Example

The following simple example shows the cutting pattern analysis of two parts from a four-point sail. It uses a static relaxation method, the flattening area is the mean surface normal and a Galerkin approach is used for the patterning method.

|

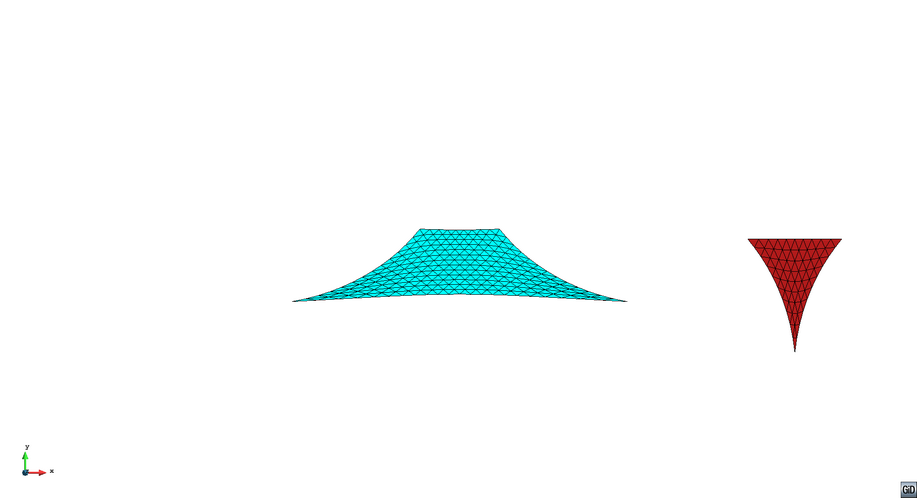

The cutting pattern of the two stripes is shown in the picture below.

|

Benchmark examples

- four point sail with coarse discretization: ..\examples\benchmark_examples\analyses\cutPat_Membrane1\cbm_CutPat.dat

- four point sail with coarse discretization and automatic mounting analysis after restart: ..\examples\benchmark_examples\analyses\cutPatWithMounting_Membrane1\cbm_CutPatWithMounting.dat

- four point sail with linear elastic material and membrane 1 elements (not included in regular benchmarks due to amount of time for running, but working!) ..\examples\benchmark_examples\analyses\cutting_patterning_membrane1_I\x_cbm_4_point_patterning.txt

References

- ↑ Dieringer, F.: Numerical Methods for the Design and Analysis of Tensile Structures, Dissertation Lehrstuhl für Statik, 2014

| Whos here now: Members 0 Guests 0 Bots & Crawlers 1 |