Users:General FEM Analysis/Analyses Reference/Cutting Pattern

| Line 75: | Line 75: | ||

|- | |- | ||

!SEAM_LENGTH | !SEAM_LENGTH | ||

| − | | | + | |to be added |

|Includes the seam lengths into the cutting pattern analysis. | |Includes the seam lengths into the cutting pattern analysis. | ||

| − | |||

|} | |} | ||

Revision as of 15:18, 30 November 2016

Contents |

General Description

Cutting pattern generation determines a plane and (optimally) stress-free geometry which can be reassembled to build a membrane with a certain prestress and shape (as it was determined in Formfinding).

Structure of Equation System

A nonlinear problem is formulated by the equation r = f_int(u) where r specifies the residual vector and f_int defines the internal forces respectively. In general, the internal forces depend on the actual displacement field u. Thus, the equation is nonlinear with respect to the a priori unknown equilibrium displacements.

At the equilibrium point the residual vector is equal to zero. The above specified nonlinear problem is linearized for the actual displacement state and solved e.g. by a Newton-Raphson scheme where the residual vector is used to compute incremental displacements by K_t u_inc = r.

Input Parameters

Parameter Description

| Compulsory Parameters | ||

| Parameter | Values, Default(*) | Description |

|---|---|---|

| PC-ANALYSIS | int : CUTTING_PATTERN | Keyword of analysis with analysis ID |

| SOLVER | PC-SOLVER int | Linking to a linear solver (direct or iterative) |

| OUTPUT | PC-OUT int | Linking to output objects (specifies the type of output format, e.g. GiD) |

| COMPCASE | LD-COM int | Linking to computation case object which specify the boundary conditions (loading and supports). Only a single computation case is allowed. |

| DOMAIN | EL-DOMAIN int | Linking to the domain the analysis should work on |

| MAX_ITER_EQUILIBRIUM | int | Maximum number of equilibrium iterations that are allowed. |

| EQUILIBRIUM_ACCURACY | float | Equilibrium accuracy that has to be reached for convergence. The convergence is checked with the L2 norm of the incremental displacements. |

| PATTERN | PART int | The parts which should be included in the analysis, separation with comma. |

| BC_CONFIGURATION | TYPE int | The type of boundary condition configuration, 4 means largest distance between the supports. For each part, one type must be given. |

| RELAXATION_METHOD | STATIC or NONE or GALERKIN or COMBINED | Definition of relaxation method. |

| FLATTENING_AREA | 0 or 1 | 0... prestress area. 1... mean surface normal. |

| PATTERNING_METHOD | GALERKIN or LS_NR or LS_CG or NONE | Definition of the patterning method. GALERKIN... principle of virtual work. LS_NR and LS_CG... optimization problem solved with Newton-Raphson or Conjugate Gradient approach. |

| Optional Parameters | ||

| SEAM_LENGTH | to be added | Includes the seam lengths into the cutting pattern analysis. |

Example of a Complete Input Block

PC-ANALYSIS 1: STA_GEO_NONLIN

PATHCONTROL = ARCLENGTH ! or DISPLACEMENT or ARCLENGTH

SOLVER = PC-SOLVER 1

OUTPUT = PC-OUT 1

COMPCASE = LD-COM 1

DOMAIN = EL-DOMAIN 1

NUM_STEP = 30

MAX_ITER_EQUILIBRIUM = 100

EQUILIBRIUM_ACCURACY = 1e-10

CURVE=LD-CURVE 1

TRACED_NODE=2

TRACED_NODAL_DOF=DISP_Y

! Example: fixed step length of 0.05

STEP_LENGTH_CONTROL = FIXED

STEP_LENGTH_CONTROL_REALS = 0.05 ! constant step length of 0.05

! Example adaptive step length according to Crisfield and Ramm

STEP_LENGTH_CONTROL = CRISFIELD_RAMM

STEP_LENGTH_CONTROL_REALS = 0.1, 1.0 ! initial step length = 0.1, exponent p = 1.0

STEP_LENGTH_CONTROL_INTS = 5 ! 5 equilibrium iterations per step are desired

! Example: no simultaneous eigenvalue analysis

SIMULTANEOUS_EIGENVALUE_ANALYSIS = 0

! Example: simultaneous eigenvalue analysis

SIMULTANEOUS_EIGENVALUE_ANALYSIS = 1

EIGEN_SOLVER = PC-SOLVER 2

! Example: use imperfect design with modes 1, 2, 4, and 6

IMPERFECTION_MODES = 1, 2, 4, 6

IMPERFECTION_SIZE = 0.015 ! maximum size of imperfection mode equals 0.015

EIGEN_SOLVER = PC-SOLVER 2

Example

The following simple example shows a geometrically nonlinear analysis of a 2bar truss system using the arclength method. It uses a fixed step size for computation. The respective input file can be found in the SVN repository under

carat20/examples/benchmark_examples/analyses/stanln_2bartruss_arclength_l/2bartruss_arclength_fixed.txt

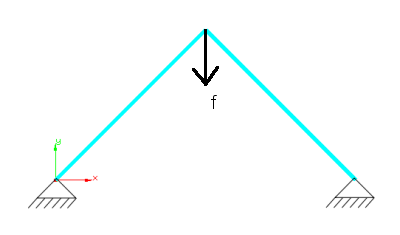

The problem computes a snap through problem. The boundary conditions are visualized by the figure below.

Simple 2bar truss structure discretized with truss elements |

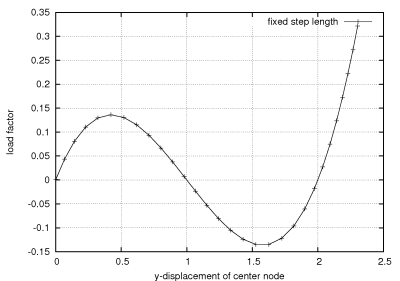

The load f is increased by the arclength method such that the displacements depicted in the figure below occur.

The figure below shows the load displacement path of the y-displacement of the center node. The well known snap through behavior is clearly visible. For a load factor of approx. 0.14 the structure shows instability. In the following the arclength control reduces the load factor until -0.14 to compute equilibrium states. Obviously these states can be only be computed by arclength or displacement control. After a complete snap through the load can be increased further. Now the complete structure works in tension which does not yield to further instability points.

References

| Whos here now: Members 0 Guests 0 Bots & Crawlers 1 |