Users:General FEM Analysis/Materials Reference/Puck Failure Criterion

| (23 intermediate revisions by 2 users not shown) | |||

| Line 2: | Line 2: | ||

== General Description == | == General Description == | ||

| − | + | Puck Failure Criterion | |

| + | <ref> | ||

| + | A. Puck: Festigkeitsanalyse von Faser-Matrix-Laminaten. Hanser, 1996. ISBN 3-446-18194-6 | ||

| + | </ref> | ||

| + | <ref> | ||

| + | H. Deuschle. 3D failure analysis of UD fibre reinforced composites: Puck’s theory within FEA. | ||

| + | Phd thesis, Universität Stuttgart, 2010. | ||

| + | </ref> | ||

| + | <ref> | ||

| + | M. Knops. Analysis of Failure in Fiber Polymer Laminates. Springer Berlin Heidelberg, Berlin, | ||

| + | Heidelberg, 2008. | ||

| + | </ref> | ||

| + | is based on Mohr‘s fracture hypothesis | ||

| + | <ref> | ||

| + | O. Mohr. Welche Umstände bedingen die Elastizitätsgrenze und den Bruch eines Materials? | ||

| + | (German). Zeitschrift des Vereins deutscher Ingenieure, 24:1524 ff, 1900. | ||

| + | </ref> | ||

| + | which is appropriate for brittle fracture behaviour of composite materials. It can distinguish between fibre fracture and different inter-fibre fracture. Both 2D and 3D formulations are implemented into Carat++. | ||

Available fracture modes for 2D Puck Criterion are: | Available fracture modes for 2D Puck Criterion are: | ||

* Fibre Fracture (FF) | * Fibre Fracture (FF) | ||

| Line 12: | Line 29: | ||

* Inter Fibre Fracture (IFF) | * Inter Fibre Fracture (IFF) | ||

| − | === Parameter Description | + | == Stresses on the Fracture Plane == |

| + | |||

| + | [[File:formel3.1.png|300px]] | ||

| + | |||

| + | [[File:formel3.2.png|150px]] | ||

| + | |||

| + | [[File:formel3.3_2.png|150px]] | ||

| + | |||

| + | [[File:Figure 3.4.png|500px]] | ||

| + | |||

| + | Stresses of the action plane | ||

| + | <ref> | ||

| + | M. Knops. Analysis of Failure in Fiber Polymer Laminates. Springer Berlin Heidelberg, Berlin, | ||

| + | Heidelberg, 2008. | ||

| + | </ref> | ||

| + | |||

| + | |||

| + | == Strength Analysis == | ||

| + | |||

| + | In order to judge if a stress vector on the stress spce is leading to damage, a mathematical expression is needed. | ||

| + | This expression is called ''fracture condition'' an is written as the following general form: | ||

| + | |||

| + | |||

| + | [[File:Formel3.4.png|150px]] | ||

| + | |||

| + | |||

| + | [[File:sigma_i.png|15px]] : Components of stress vector | ||

| + | |||

| + | R<sub>i</sub>. : Strengths under corresponding stresses | ||

| + | |||

| + | F : Fracture function | ||

| + | |||

| + | |||

| + | There are 6 main strengths that should be related to the occurring stress state: | ||

| + | |||

| + | [[File:6main_strengths.png|350px]] | ||

| + | |||

| + | The general form of fracture condition can also be rewritten as following: | ||

| + | |||

| + | [[File:Formel3.5.png|350px]] | ||

| + | |||

| + | F < 1 : no fracture | ||

| + | |||

| + | F = 1 : fracture limit reached and fracture occurs | ||

| + | |||

| + | F > 1 : fracture limit exceeded | ||

| + | |||

| + | with F [[File:Element.png|10px]] [0,[[File:unendlich.png|18px]]) | ||

| + | |||

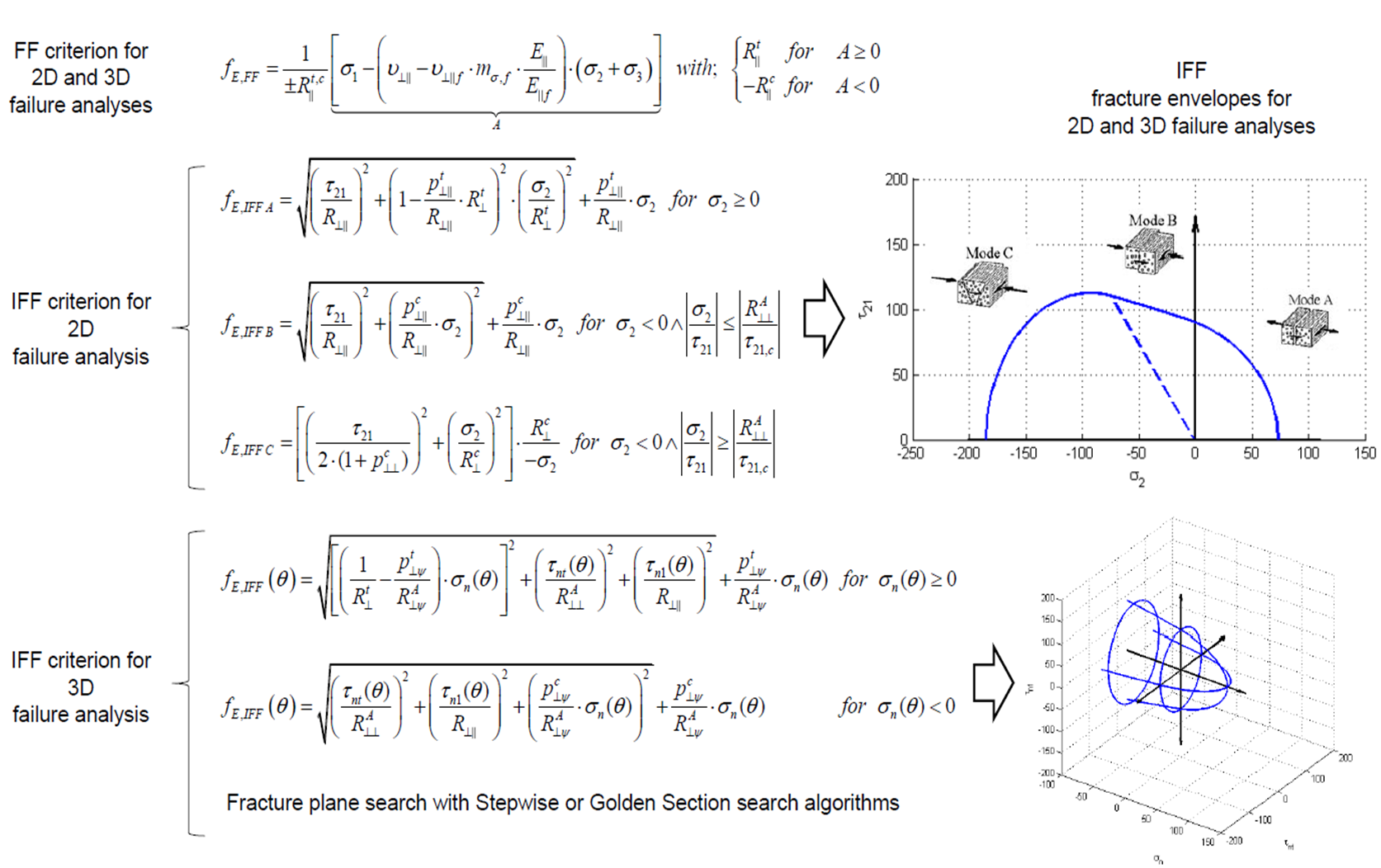

| + | [[File:puck.png|1000px]] | ||

| + | <ref> | ||

| + | Altug Emiroglu, Master Thesis: Comparative Study of Puck and Tsai-Wu Failure Criteria, Technische Universität München, 2013. | ||

| + | </ref> | ||

| + | |||

| + | |||

| + | == Parameter Description == | ||

{| border="1" cellpadding="3" cellspacing="0" | {| border="1" cellpadding="3" cellspacing="0" | ||

| Line 55: | Line 127: | ||

!PCTL | !PCTL | ||

|real | |real | ||

| − | |Inclination parameter, | + | |Inclination parameter,[[File:pc.png|25px]] |

|- | |- | ||

| Line 78: | Line 150: | ||

!S, M | !S, M | ||

|real | |real | ||

| − | |Parameters necessary for calculation of weakening due to | + | |Parameters necessary for calculation of weakening due to [[File:sigma.png|20px]] (''De f ault'' = S = M = 0.5) |

|- | |- | ||

!PTT | !PTT | ||

|real | |real | ||

| − | |Inclination parameter p | + | |Inclination parameter [[File:p.png|25px]]. When not given, calculated using the strength values. See Section 3.1.2.3 |

|- | |- | ||

!WEAKENING | !WEAKENING | ||

|int | |int | ||

| − | |Switch for calculation of weakening due to | + | |Switch for calculation of weakening due to [[File:sigma.png|20px]]. |

* 0 = OFF | * 0 = OFF | ||

* 1* = ON | * 1* = ON | ||

| Line 102: | Line 174: | ||

|- | |- | ||

|} | |} | ||

| + | |||

| + | |||

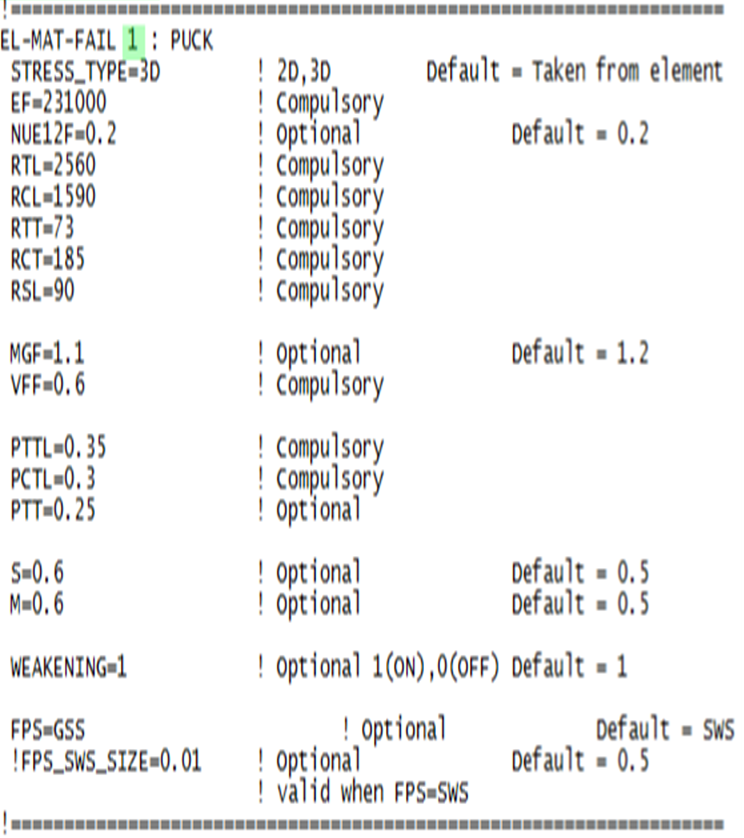

| + | === Example of a Complete Input Block === | ||

| + | [[File:input_puck.png|500px]] | ||

| + | |||

| + | |||

| + | == References == | ||

| + | <references/> | ||

Latest revision as of 10:05, 15 February 2013

Contents |

General Description

Puck Failure Criterion [1] [2] [3] is based on Mohr‘s fracture hypothesis [4] which is appropriate for brittle fracture behaviour of composite materials. It can distinguish between fibre fracture and different inter-fibre fracture. Both 2D and 3D formulations are implemented into Carat++. Available fracture modes for 2D Puck Criterion are:

- Fibre Fracture (FF)

- Inter Fibre Fracture Mode A (IFF A)

- Inter Fibre Fracture Mode B (IFF B)

- Inter Fibre Fracture Mode C (IFF C)

Available fracture modes for 3D Puck Criterion are:

- Fibre Fracture (FF)

- Inter Fibre Fracture (IFF)

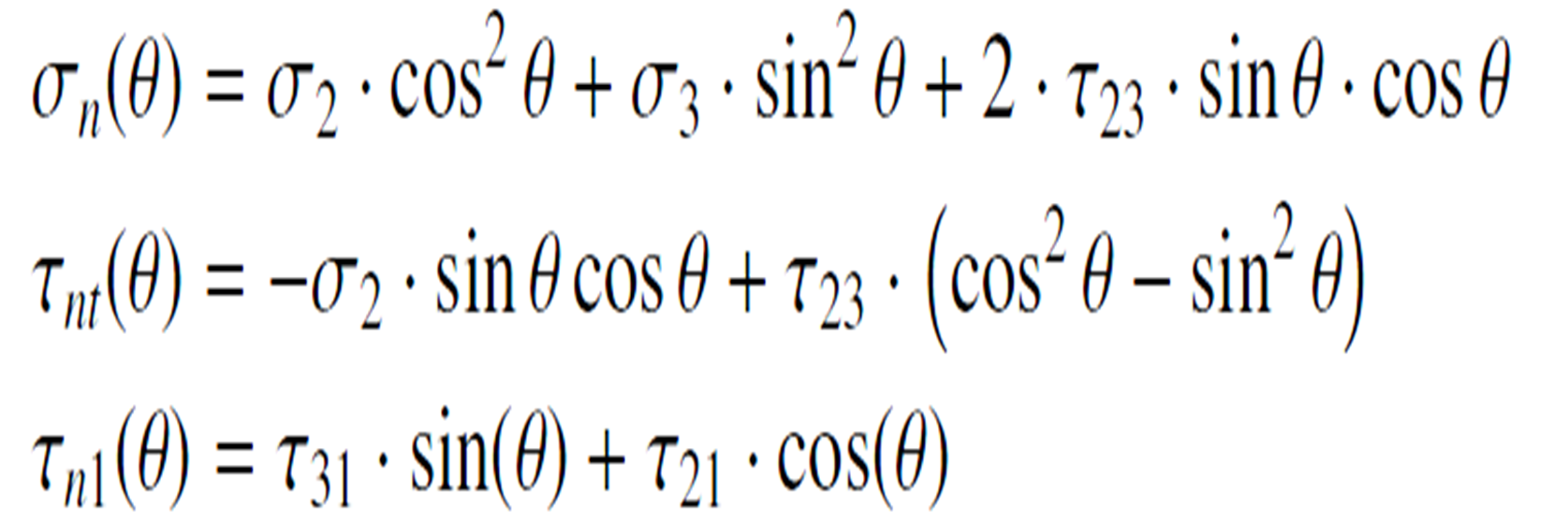

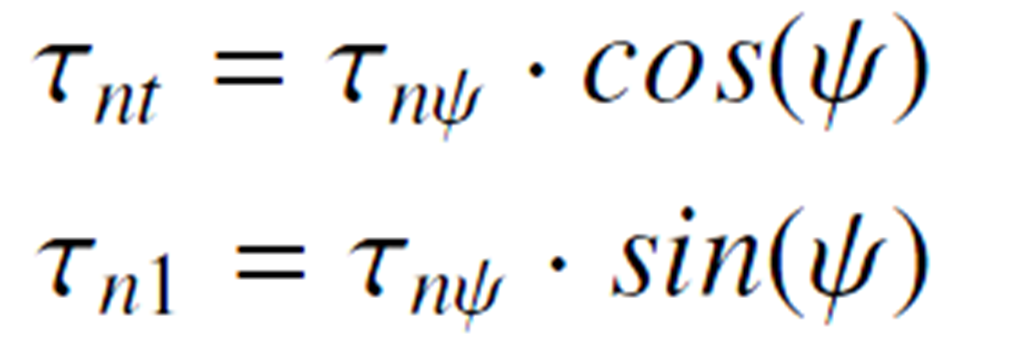

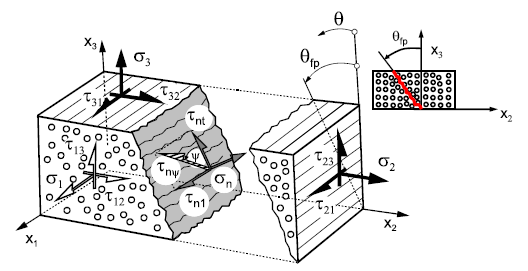

Stresses on the Fracture Plane

Stresses of the action plane [5]

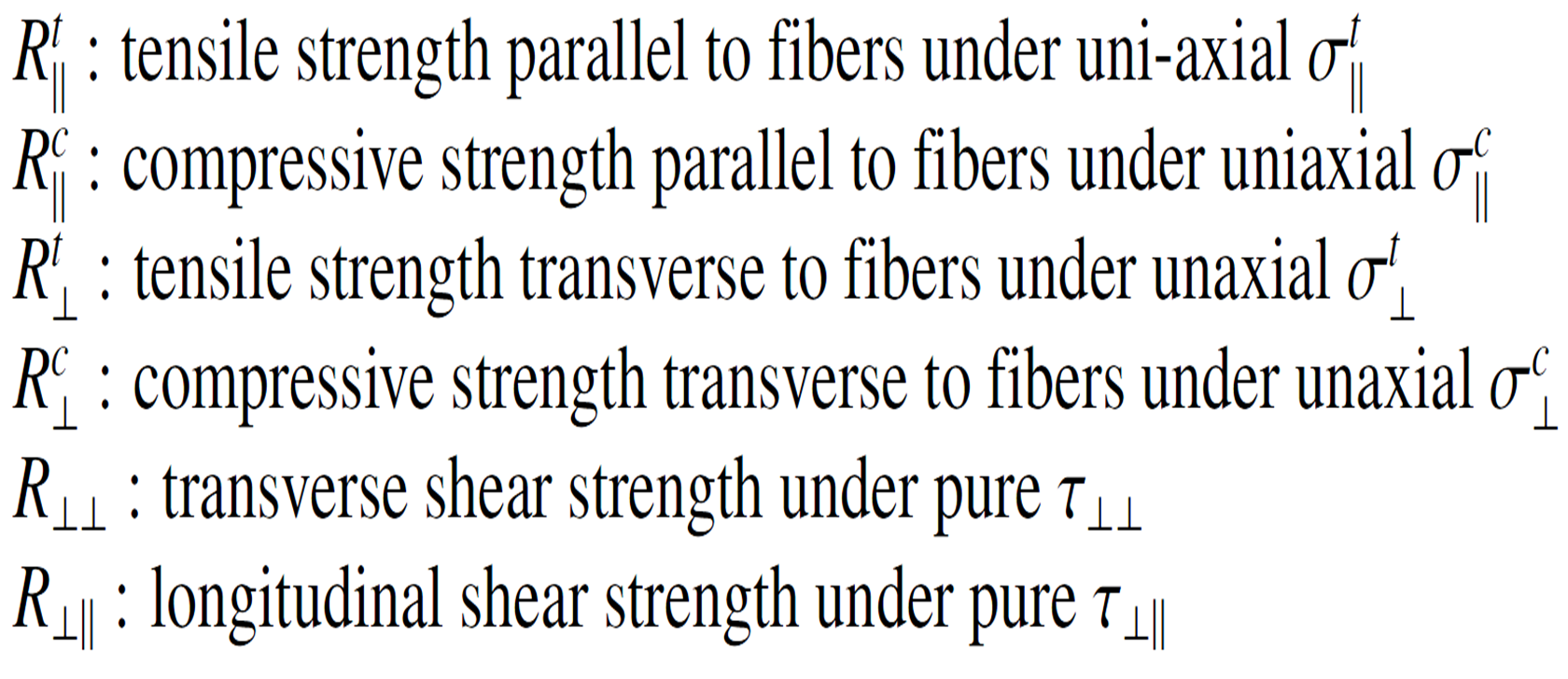

Strength Analysis

In order to judge if a stress vector on the stress spce is leading to damage, a mathematical expression is needed. This expression is called fracture condition an is written as the following general form:

Ri. : Strengths under corresponding stresses

F : Fracture function

There are 6 main strengths that should be related to the occurring stress state:

The general form of fracture condition can also be rewritten as following:

F < 1 : no fracture

F = 1 : fracture limit reached and fracture occurs

F > 1 : fracture limit exceeded

Parameter Description

Example of a Complete Input Block

References

- ↑ A. Puck: Festigkeitsanalyse von Faser-Matrix-Laminaten. Hanser, 1996. ISBN 3-446-18194-6

- ↑ H. Deuschle. 3D failure analysis of UD fibre reinforced composites: Puck’s theory within FEA. Phd thesis, Universität Stuttgart, 2010.

- ↑ M. Knops. Analysis of Failure in Fiber Polymer Laminates. Springer Berlin Heidelberg, Berlin, Heidelberg, 2008.

- ↑ O. Mohr. Welche Umstände bedingen die Elastizitätsgrenze und den Bruch eines Materials? (German). Zeitschrift des Vereins deutscher Ingenieure, 24:1524 ff, 1900.

- ↑ M. Knops. Analysis of Failure in Fiber Polymer Laminates. Springer Berlin Heidelberg, Berlin, Heidelberg, 2008.

- ↑ Altug Emiroglu, Master Thesis: Comparative Study of Puck and Tsai-Wu Failure Criteria, Technische Universität München, 2013.

| Whos here now: Members 0 Guests 0 Bots & Crawlers 1 |