Users:General FEM Analysis/Elements Reference/SolidHexa1

(→The EAS Method) |

(→Element Type) |

||

| (19 intermediate revisions by one user not shown) | |||

| Line 5: | Line 5: | ||

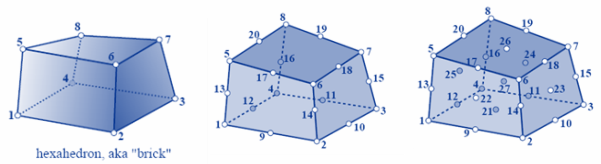

[[File:Element_hexa_topo.png|400px|border|up|Topology of SolidHexa1 elements]] | [[File:Element_hexa_topo.png|400px|border|up|Topology of SolidHexa1 elements]] | ||

| − | + | <ref> | |

| + | Pictures taken from the notes to the lecture "Advanced Finite Element Methods for Solids, Plates and Shells" given by Carlos Felippa at the University of Colorado at Boulder. | ||

| + | http://www.colorado.edu/engineering/CAS/courses.d/AFEM.d/ (4th August 2011) | ||

| + | </ref> | ||

=== Element Type === | === Element Type === | ||

* This element class provides 3D hexahedral elements with linear (8-noded element), partially quadratic (20-noded) or quadratic shape functions (27-noded) | * This element class provides 3D hexahedral elements with linear (8-noded element), partially quadratic (20-noded) or quadratic shape functions (27-noded) | ||

| − | * The element formulation includes an enhanmced assumed strain ('''EAS''') improvement in order to avoid locking effects. This feature is only available for 8-noded elements | + | * The element formulation includes an enhanmced assumed strain ('''EAS''') improvement in order to avoid locking effects. This feature is only available for 8-noded elements. EAS can be used within gemoetrical nonlinear analysis, but it might lead to '''artificial uero energy modes''' within the regime of big strains. <ref> W. A. Wall, M. Bischoff, E. Ramm: „A deformation dependent stabilization technique, |

| − | + | exemplified by EAS elements at large strains“, in „Computer methods in applied | |

| + | mechanics and engineering“, Vol. 188, 2000, Seiten 859-871 </ref> | ||

=== Degrees of Freedom === | === Degrees of Freedom === | ||

| Line 100: | Line 104: | ||

<pre> | <pre> | ||

LD-ELEM 1 | LD-ELEM 1 | ||

| − | + | TYPE = TEMPERATURE | |

ND-SET = 1 LAYER = 1 VAL = +10 | ND-SET = 1 LAYER = 1 VAL = +10 | ||

ND-SET = 2 LAYER = 1 VAL = -10 | ND-SET = 2 LAYER = 1 VAL = -10 | ||

| Line 107: | Line 111: | ||

== The EAS Method == | == The EAS Method == | ||

The idea of enhanced assumed strains is to enlarge the element srain field by a set of additional strains in order to enable the element to express certain states of displacement without locking due to parasitic strains. | The idea of enhanced assumed strains is to enlarge the element srain field by a set of additional strains in order to enable the element to express certain states of displacement without locking due to parasitic strains. | ||

| − | <ref J.C. Simo, M.S. Rifai: „A class of mixed assumed strain methods and the method | + | <ref> |

| − | of incompatible modes“, in „International Journal for Numerical Methods in | + | J.C. Simo, M.S. Rifai: „A class of mixed assumed strain methods and the method |

| − | + | of incompatible modes“, in „International Journal for Numerical Methods in Engineeering“, Vol. 29, 1990, pages 1595-1638 | |

| + | </ref> | ||

<ref name="AnRa93"> U. Andelfinger, E. Ramm: „EAS-Elements for two-dimensional, three-dimensional, | <ref name="AnRa93"> U. Andelfinger, E. Ramm: „EAS-Elements for two-dimensional, three-dimensional, | ||

plate and shell structures and their equivalence to HR-Elements“, in „International | plate and shell structures and their equivalence to HR-Elements“, in „International | ||

| − | Journal for Numerical Methods in Engineeering“, Vol. 36, 1993, pages 1311-1337 </ref>. | + | Journal for Numerical Methods in Engineeering“, Vol. 36, 1993, pages 1311-1337 </ref>. |

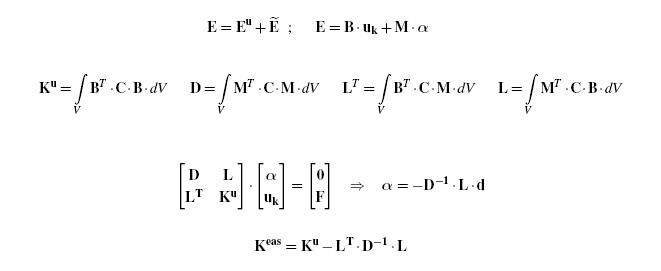

To this purpose the strain-displacement relation is enlarged by additional terms which leads to a modified element stiffness matrix: | To this purpose the strain-displacement relation is enlarged by additional terms which leads to a modified element stiffness matrix: | ||

| Line 119: | Line 124: | ||

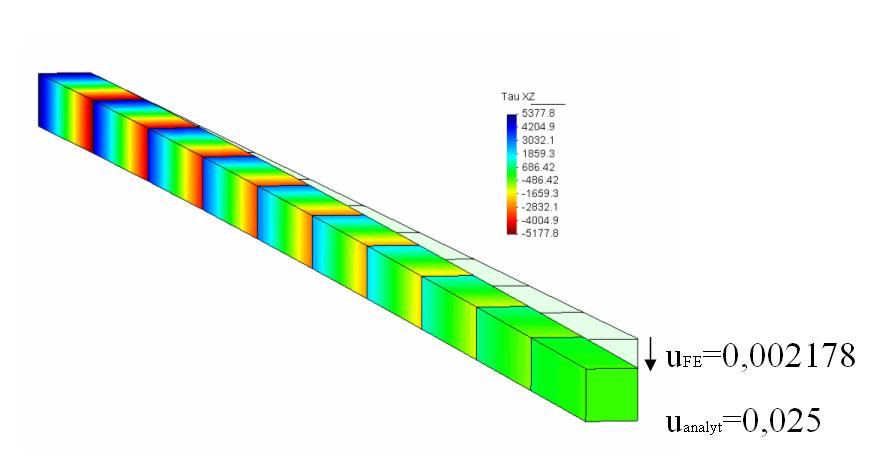

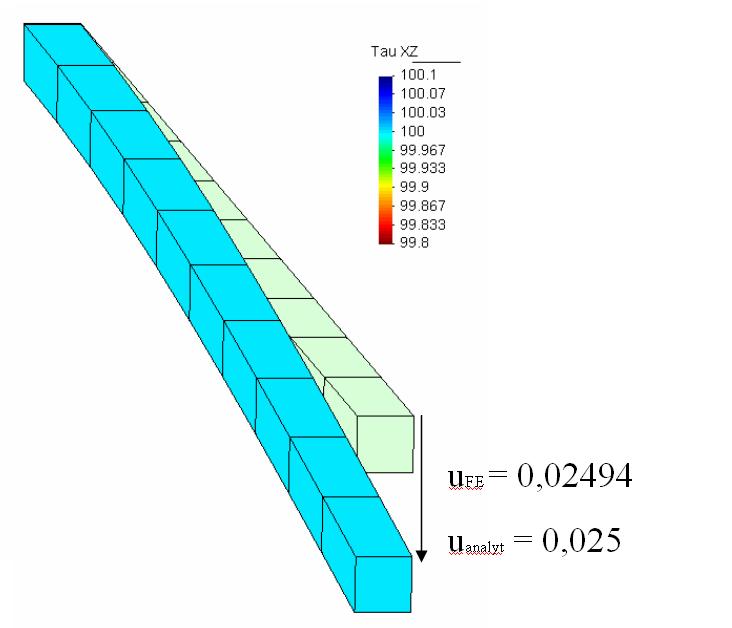

The following example will show the benefit of EAS improved elements toward purely displacment formulated eight-noded hexahedrals. The investigated system is a tip loaded cantilever wherby the cross section is modeled by one element. | The following example will show the benefit of EAS improved elements toward purely displacment formulated eight-noded hexahedrals. The investigated system is a tip loaded cantilever wherby the cross section is modeled by one element. | ||

| − | + | {|border="1" | |

| − | File:Cantilever_locking.JPG | HEXA8 | + | |[[File:Cantilever_locking.JPG |400px| HEXA8]] |

| − | File:Cantilever_lockingfree.JPG | HEXA8EAS9 | + | |[[File:Cantilever_lockingfree.JPG |400px| HEXA8EAS9]] |

| − | + | |- | |

| + | | Element HEXA8 | ||

| + | | Element HEXA8EAS9 | ||

| + | |} | ||

The pure displacement based elements show the well known in-plane shear locking which increases along the cantilever with increasing bending moment. As artificial strain/shear produces artificial stiffness, the tip displacement is extremly under estimated. | The pure displacement based elements show the well known in-plane shear locking which increases along the cantilever with increasing bending moment. As artificial strain/shear produces artificial stiffness, the tip displacement is extremly under estimated. | ||

Latest revision as of 08:07, 4 August 2011

Contents |

General Description

Element Type

- This element class provides 3D hexahedral elements with linear (8-noded element), partially quadratic (20-noded) or quadratic shape functions (27-noded)

- The element formulation includes an enhanmced assumed strain (EAS) improvement in order to avoid locking effects. This feature is only available for 8-noded elements. EAS can be used within gemoetrical nonlinear analysis, but it might lead to artificial uero energy modes within the regime of big strains. [2]

Degrees of Freedom

All hexahedral elements use three translatoric degrees of freedom at each node.

They are named Disp_X, Disp_Y, Disp_Z.

Input Parameters

Parameter Description

| Compulsory Parameters | ||

| Parameter | Values, Default(*) | Description |

|---|---|---|

| MAT | EL-MAT int | Linking to a material input block |

| INT_TYPE_HEXA | FULL, REDUCED | Control of integration type 20-noded elements are able to perform a uniform reduced integration (2x2x2 instead of 3x3x3) without hourglassing stabilisation |

| Optional Parameters | ||

| Parameter | Values, Default(*) | Description |

| EAS | int | Flag Enhances Assumed Strains (EAS) method Possible values are:

|

Example of a Complete Input Block

EL-PROP 1: SOLIDHEXA1 MAT = EL-MAT 1 INT_TYPE_HEXA = FULL EAS = 0

Inside the property block there is no distinction between linear and quadratic formulated elements. It is possible to define 8-noded, 20-noded and 27-noded elements using one and the same element property (assuming that no EAS is used):

! ElementID Part-ID EL-PROP Node-IDs NEL 1 1 1 1 2 3 4 5 6 7 8 ! 8-noded element NEL 2 1 1 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 36 38 39 40 !20-noded element NEL 3 1 1 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 66 68 69 70 71 72 73 74 75 76 77 !27-noded element

Element Loading

Hexahedral elements are able to carry two types of element loads:

- dead load

- temperature load

Dead Load

Dead weight of an element is computed by multiplying material's denisity (ρ) with gravity's acceleration, which has to be defined inside the load block concearning its direction and size.

An example for a load definition of a concrete structure (assuming linear elastic isotropic material behaviour) with gravity acting in positive z-direction would look like

EL-MAT 1 : LIN_ELAST_ISOTROPIC EMOD=3.5e10 ALPHAT=1e-5 DENS=2.5e3 NUE=0.2

LD-ELEM 1 PART=1 TYPE=DEAD D1=0.0 D2=0.0 D3=1.0 VAL=9.81

whereat the finite elemet model is based on SI units (m, N, kg).

Temperature Load

This paragraph only focuses at element specific topics concearing temperature load. For more detailed descriptions please look at the load documentation

For the computation of temperature loads solid elements do not concider any layer of laminate structure within the element. So only the temperature defined for layer number one is considered at each node.

The combination of temperature loading and EAS improvement is possible.

LD-ELEM 1 TYPE = TEMPERATURE ND-SET = 1 LAYER = 1 VAL = +10 ND-SET = 2 LAYER = 1 VAL = -10

The EAS Method

The idea of enhanced assumed strains is to enlarge the element srain field by a set of additional strains in order to enable the element to express certain states of displacement without locking due to parasitic strains. [3] [4].

To this purpose the strain-displacement relation is enlarged by additional terms which leads to a modified element stiffness matrix:

The following example will show the benefit of EAS improved elements toward purely displacment formulated eight-noded hexahedrals. The investigated system is a tip loaded cantilever wherby the cross section is modeled by one element.

|

|

| Element HEXA8 | Element HEXA8EAS9 |

The pure displacement based elements show the well known in-plane shear locking which increases along the cantilever with increasing bending moment. As artificial strain/shear produces artificial stiffness, the tip displacement is extremly under estimated.

In contrast the EAS improved elements are able to eliminate artificial strains arrising from locking, and so tip displacement is described correctly.

References

- ↑ Pictures taken from the notes to the lecture "Advanced Finite Element Methods for Solids, Plates and Shells" given by Carlos Felippa at the University of Colorado at Boulder. http://www.colorado.edu/engineering/CAS/courses.d/AFEM.d/ (4th August 2011)

- ↑ W. A. Wall, M. Bischoff, E. Ramm: „A deformation dependent stabilization technique, exemplified by EAS elements at large strains“, in „Computer methods in applied mechanics and engineering“, Vol. 188, 2000, Seiten 859-871

- ↑ J.C. Simo, M.S. Rifai: „A class of mixed assumed strain methods and the method of incompatible modes“, in „International Journal for Numerical Methods in Engineeering“, Vol. 29, 1990, pages 1595-1638

- ↑ U. Andelfinger, E. Ramm: „EAS-Elements for two-dimensional, three-dimensional, plate and shell structures and their equivalence to HR-Elements“, in „International Journal for Numerical Methods in Engineeering“, Vol. 36, 1993, pages 1311-1337

| Whos here now: Members 0 Guests 0 Bots & Crawlers 1 |